Guava puree, also known as Guava pulp, is a smooth, thick substance, made by processing fresh fruit. The Guava puree retains all of the sweetness, flavor, and nutrients in the fresh fruits. The Guava puree is manufactured from guava fruits that have been carefully sorted. The guava processing in India is well equipped with advanced technology and state of art manufacturing facilities to meet the demand of the domestic and international markets. The fruit juice sector is the major user of guava puree.

Global guava Production

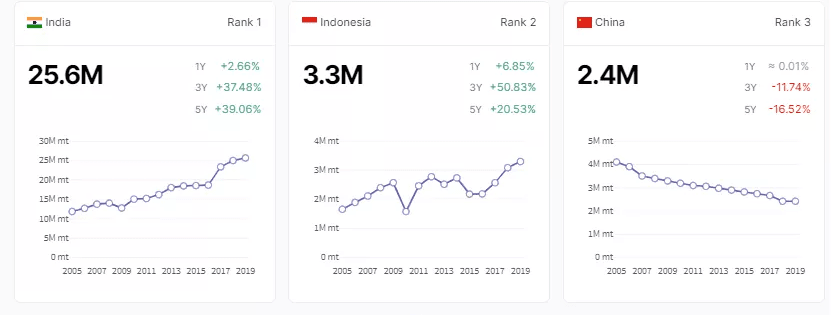

There are around 400 varieties of guava cultivated in the world. Only a few dozen varieties are commercially Cultivated. India is the world’s largest producer of Guava that produces 25M tonnes of guava every year. India contributes to 45% of the world’s guava production followed by Indonesia, China, and Mexico.

South America produces a small amount of guava puree and concentrates. But it is consumed domestically and in North America. Some African countries cultivate guavas and produce guava puree. However, the processing plants are inconveniently located. Since guava is a tropical fruit and the climatic conditions are favorable to India, it leads the guava production by producing 4366300 tons every year. The buyers in Europe and the USA are paying close attention to the guava puree manufacturers in India.

Guava processing industry in India – Production capacities

Unlike mango processing facilities, the number of Guava processing units in India is limited. Guava processing industries in India are located in the region of Krishnagiri and Chittoor districts. The southern varieties are used for processing and the northern varieties are used as table varieties.

The global guava puree product was valued at $313.8 million in 2017, according to the report’s study. Over the projected period of 2017-2025, the market is expected to grow at a CAGR of 5.6%.In the next few years, the guava puree segment will maintain its dominance in the food industry. The Asia Pacific is expected to record the fastest growth during the year 2020-2025.

India is the largest producer and exporter of guava pulp. The tropical pink guava puree shares a market share of 55.3% and the white guava puree shares a market share of 40%. The remaining 5% is shared by the other varieties. In addition, the lack of technology for guava processing has slowed the global guava industry’s development. However, in recent years, the development of superior post-harvest technology has benefited the food and beverage processing industry. Furthermore, substantial advancements in the food processing industry enhance the worldwide guava puree market.

Guava pulp Processing method

The matured guavas are brought to our factory and transferred to the ripening chambers. The Guavas are ripened naturally. The damaged guavas are sorted out in the conveyor belt. The fruits are washed with chlorinated and freshwater to remove dirt. The fruits are passed through the fruit miller and the pulp is collected in the pulp collection tank.

The pulp is collected in the pulp storage tank, and the product is preheated at 65-70 deg C. The grit level in the guava puree is regulated by a decantation process. To produce concentrate products, the pulp is passed through the evaporator to remove the water content. The pulp is passed through a magnetic trap, online strainer, and metal detector The sterilization process removes pathogens and other microorganisms from the guava puree. The puree is cooled and filled in aseptic bags in MD drums with polyliner inside. The products are stored under temperature controlled warehouses.

Processing varieties of Guava in India

White guava and Pink guava are the most popular varieties of guava processed in India. Lucknow variety (White guava), and Desi Karnataka (Pink guava) are the popular varieties of guava processed in India. Other varieties are processed in small quantities and are mostly used as a table variety. There are two peak seasons for guava pulp in India. One is from January – March and the other one is from August- December.

White guava pulp

The Lucknow variety is grown in the region of Andhra Pradesh and is known for its nutrition, flavor and taste. This is the most commercial variety of guava preferred by Guava pulp manufacturers. White guava puree has a great demand in both domestic and international markets.

- Brix: 9 Deg

- Packaging: Aseptic white guava pulp is packed aseptically in pre-sterilized aseptic bags placed with poly-liner in food-grade epoxy painted (inside) open-top MS drum.

- Gross weight: 18MT (80 drums in 20 FCL)

- Shelf life: 24 months from the date of manufacturing

- Product Net weight: 210 kgs / Drum

Pink Guava pulp

Pink guava varieties are grown in the region of Karnataka and Andhra Pradesh. Desi Karnataka is one of the important commercial varieties of guava, due to its sweetness, and higher pulp content. Pink guava puree and pink guava concentrate are preferred by guava-based beverage manufacturers. Pink guava varieties (Taiwan and Arka Kiran) are used as table varieties.

- Brix: 8 Deg

- Packaging: Aseptic pink guava pulp is packed aseptically in pre-sterilized aseptic bags placed with poly-liner in food-grade epoxy painted (inside) open-top MS drum.

- Gross weight: 18MT (80 drums in 20 FCL)

- Product Net weight: 210 kgs / Drum

- Shelf life: 24 months from the date of manufacturing.

Usage of Guava process products.

The primary guava processing products are Guava puree, pulp, and concentrate. The primary guava processed products create scope for secondary guava products. Guava is the most popular flavoring agent in Europe and the United States. The beverage industries in these regions strongly emphasize guava puree, while actual guava fruit consumption remains modest. Most of the trade that occurs through guava is in the form of puree and concentrates.

Major secondary guava processed products include jellies, jams, marmalade, filling of baked goods, sweets and drinks, and fruit-based cosmetics that contain fruit extracts. In addition to ready to drink beverages, guava processed products are used in powder mixes or squashes for preparing refreshment drinks.

With the increase in the consumption of Guava processed products in the confectionery and dairy industry, the usage of puree in bakery fillings, puddings, ice-cream mixes, and fruit meals for children is expected to increase the market growth. The guava puree and concentrate in the beverage industry impart the guava’s unique taste and flavor in the final product.

Future trends in the Guava processing industry

Consumers in the developed and developing nations are drawn to ready to drink beverages and ready to eat foods due to disposable income and rapid urbanization. Processed food manufacturers and guava pulp processing industries are shifting their focus to ready to eat food products to meet the growing demand. The majority of the fruit juice manufacturers use Guava puree instead of adding flavoring additives. The guava pulp retains the fresh flavor of the guava fruit, which aids in taste and product quality. Consumer’s changing lifestyle and food habits significantly contribute to the expansion of ready to eat food items. With the rising requirements for fruit pulp instead of fresh fruits, the market for mango puree products is predicted to increase.

Key opportunities for the Guava pulp processing industries

The major factor driving global consumer demand for fruit pulp is a long storage life without considerable change to the natural content and taste. Longer shelf life corresponds to lower transportation and storage costs, which encourages fruit puree manufacturers to boost output. Due to the growing numbers of consumers seeking natural products, the organic food business is predicted to grow significantly in terms of sales volume and consumption.

Guava pulp processing industries are expected to target the organic segment to maintain a solid position in the global market. Existing Guava pulp industries are investing in Research and Development to create new products that meet customer demands. The increasing use of guava pulp in the retail household is likely to generate numerous opportunities in the guava processing industry.

Comments (3)

Prabhu meti

Where are the pulp processing units, I want visit some of the processing units.

Madhura milind govande

महाराष्ट्रात पेरूचा लगदा करणाऱ्या कंपन्या कुठे आहेत ? त्या कंपन्यांना भेट देऊन माहिती घेता येईल का?

Sriram AS

ज़रूर, आप हमारी सुविधा का दौरा कर सकते हैं। कृपया हमसे संपर्क करें: https://abcfruits.com/contact/