Mango sustainability – Overview

Environment Sustainability is a responsibility dedicated to maintaining the quality of our planet through eco-friendly and biological practices. At ABC Fruits, we believe “a healthy planet is the backbone of every industry on earth”. The postharvest losses of mango fruit have been estimated to be as high as 50% in Asia and Africa, especially during the peak mango season. The processing industries in the developing nations serve a critical role in the processing of mango wastes as sustainable energy to reduce post-harvest losses and create a healthier environment. The byproducts of mangoes are used in various applications, thereby gaining greater value and reducing wastage.

Mango Waste generation and its impact on the environment

The Mango processing industry and value-added products produce a huge quantity of waste, mostly in the form of peels, seeds and fibre. Based on the variety of mango, the mango seed accounts for 20-60% of the fruit weight. The mango kernel inside the seed accounts for 45-75% of the seed’s weight. The edible fruit is It has been reported that the mango seed is one of the most common agro-industrial byproducts that generate about 123000 tonnes of waste annually.

The peels and fibre of the mangoes make up 7-24% of the total weight of the fruit. The mango processing industries generate millions of tonnes of solid waste, approximately 40-50% of the raw material. The volumes of mango processing wastes are expected to increase further because of the increase in mango production and mango processing plants. The waste will create an adverse impact on the environment. Hence, proper solid waste management has become requisite for the fruit processing industries.

Mango solid wastes

There are more than 30 mango processing industries located in the Krishnagiri district. Each unit produces about 5000-7000 tonnes of solid waste every year. The solid wastes include Mango kernel (seeds), Mango fibre and peels. Most of these wastes are thrown on the roadsides and dumped in the living areas.

The disposal of fruits has always been a difficulty for the processing industries due to high transportation costs and the unavailability of landfills. The improper disposal causes a severe environmental impact. The residues of these wastes penetrate the soil and affect the quality of the groundwater. This causes severe problems to humans, animals and the environment. Uncontrolled gas production can also lead to global warming. To avoid this, We have come up with solid waste management that puts the environment as a priority before profits.

Utilization of mango wastes at ABC Fruits

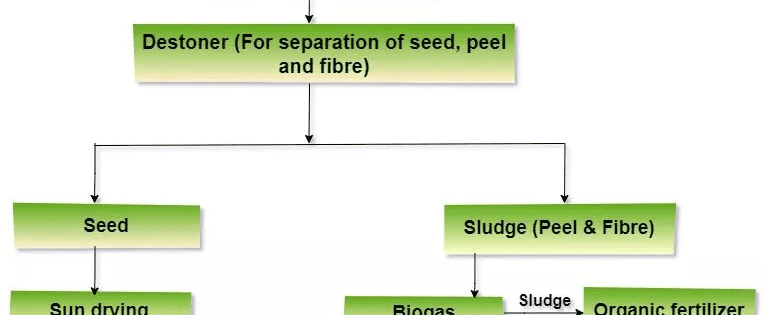

- At ABC Fruits, We are equipped with Destoner machinery that separates peels, fibre, and seeds from the mango fruit.

- These peels, seeds and fibre are segregated and collected on the trucks for waste management.

- The seeds are sun-dried on the granite floor and later used as a boiler feed.

- The kernel in the seeds is also sent to mango butter and oil production

- The sludges, peels and fibre are sent to the biogas plant to produce biogas. These biogases are also used as a feed to the boiler.

- The treated sludge at the biogas plant is used as a fertilizer and manure for farming.

Biogas production at ABC Fruits

The implementation of biogas production at our plant decreases our dependency on fossil fuels and makes waste into useful conversion. We use mango peels and fibre for the production of biogas. The mango peels are capable of producing 0.33m 3biogas/kg total solids and a methane concentration of 53% after a 15day hydraulic retention time. The output produced from the biogas plant can be used for numerous applications. It can also be used to run the generator to produce electricity. However, We use it as a feed to the boiler in place of firewood. The slurry/sludge present in the biogas plant is further used as a fertilizer / organic manure for farming.

Effluent treatment plant

Effluent treatment plants play a vital role in treating industrial wastewater for its reuse or safe disposal into the environment. At our factory, we have installed ETP systems that preserve the environment against water pollution, reduce freshwater usage, and reduce the expenditure on water acquisition. At ABC Fruits, the clean water output from the ETP plant is used for farming.

The wastewater entering the ETP plants goes through various processes before we let the water for irrigation. The suspended particles and other contaminants are filtered out in the process. As a first stage in the process, the wastewater is collected in the Equalization tank that passes the water to the rest of the ETP process at steady rates. The primary clarifier helps the heavier solid to settle down at the bottom of the tank.

The anaerobic process is carried out in the anaerobic reactor where the organic wastes are treated which are later removed as a sludge. Then the water is passed through the aeration tank where the air is passed through the wastewater to remove CO2 and other contaminants. The secondary clarifier further filters and removes activated sludge. The activated carbon filter tank removes certain chemicals and odours from the water. Eventually, the pressure sand filter which has multiple layers of sand removes the suspended particles before letting out the water for irrigation.

ABC Fruit’s sustainability best practices

- We are using 10000 tonnes of mango seeds as a feed for the boiler every year. This reduces the dumping of seeds in landfills.

- We also supply the peels and fibres to the Indian Oil Corporation for the production of biogas. IOCL produces 45kgs of biogas from 1-ton mango wastes.

- The production of biogas reduces the usage of CO2 and other greenhouse gasses. This reduces carbon footprint to a great extent.

- Since the wastewater is recycled with the help of ETP, the need for additional water is reduced for farming which saves water in huge quantities.

- We also supply the mango waste products to small-scale manufacturers who produce value-added products from the wastes that include (mango seed powder, mango butter and other health-related products).

1 Comment

Kamlesh Rana

Nice Article

I have project similar;