What is fruit pulp – Definition

Fruit pulp is a product produced by processing fresh fruits. The fruit pulp processing involves the crushing of the fruit, sterilizing and packing it as per the customer’s requirements. The difference between fruit pulp and fruit puree is nothing but the pronunciation. Fruit pulp is also referred to as fruit puree in Western countries. In some countries, fruit pulp is also termed NFC (Not from Concentrate) and Single-strength puree. The fruit pulp retains all of the juice and pulp and only the excess fiber is removed.

To know the difference between fruit puree and concentrate click here https://abcfruits.com/difference-between-puree-concentrate/

Fruit Puree Shelf Life

With the help of technological advancement in the Food and beverage industry, Fruit pulp can now be stored for longer periods without changing its nutrition benefits, colour, flavour, texture and aroma. The fruit pulp’s shelf life is also extended without adding any preservatives and can be used for 24 months with aseptic packaging.

What is fruit pulp used for?

Fruit pulp is an essential ingredient in the manufacturing of beverages and fruit-related products. It is used in various food processing industries that include beverages, Dairy industry, Icecreams, Yogurts, baby foods, Jams, Fruit squash, confectionaries, Bakery items and even cosmetic industries.

Before you use fruit pulp, whether it is for small culinary applications or a large beverage manufacturing industry it is a must to know each type of fruit pulp based on the processing, application, packaging and storage.

Fruit pulp Applications by Industry:

-

- Beverages: Fruit puree is a versatile ingredient in the beverage industry. It is used for manufacturing beverages, nectars, smoothies, mocktails, and flavour-based drinks.

- Dairy: Fruit puree is used in the dairy industry for manufacturing flavoured yoghurts, ice cream, and milkshakes.

- Bakery and confectionary: It can be used in bakery fillings, toppings, jellies, cakes and fruit-infused tarts.

- Processed foods: It is widely used in manufacturing fruit jams, candies, fruit squash, and even fruit bars.

- Nutraceutical and health supplements: Fruit pulps are utilized in the production of nutraceuticals, dietary supplements, and health drinks due to their high nutritional content and natural antioxidants.

- HORECA: Canned fruit pulps are used to produce mocktails, desserts, smoothies and salads.

What are the different types of fruit pulp and how are they processed differently?

Aseptic Fruit pulp

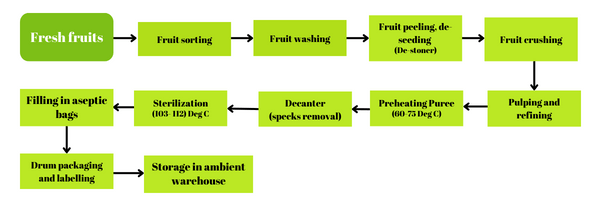

How it is processed

- Fruits are sorted and washed. Unripe and damaged fruits are removed.

- The fruit peels, stone, and fibre are removed and crushed to produce fruit pulp.

- The fruit pulp is collected in the pulp collection tank and preheated at 60-75 degrees Celsius.

- The product is sterilized and packed in aseptic bags in MS Drums.

To learn more about the fruit pulp processing method for various tropical fruits click here https://abcfruits.net/process-methods/

Handling and storage: The product is stored at ambient temperature and has a shelf life of 24 months.

Organoleptic features: The flavour, aroma, and taste of the pulp retains the nature of the original fruit as no preservatives are added.

Packaging & Loading: Aseptically in pre-sterilized aseptic bags placed with polyliner in food grade epoxy painted (inside) open-top MS drum. 80 Drums Per 20-foot Container and 112 drums in a 40 ft container.

Aseptic Fruit concentrate/ Fruit puree concentrate/ Juice concentrate

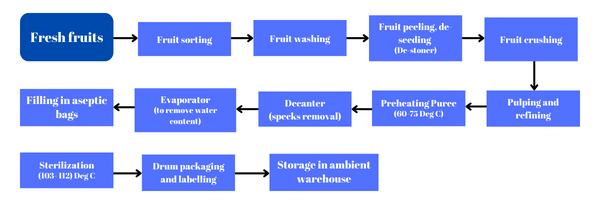

- The aseptic fruit concentrate process begins with washing the fruits with fresh and chlorinated water.

- The fruits are sent to the fruit crusher/ miller to produce fruit pulp.

- The fruit pulp is collected in the standardisation tank and preheated.

- The product is passed through a strainer to remove grit and impurities.

- Eventually, to produce fruit concentrate, the fruit pulp is passed through the evaporator.

- The evaporator removes the water content from the pulp to produce fruit puree concentrate/ Juice concentrate.

- The product is filled in Aseptic bags in MS drums and stored in a temperature-controlled warehouse.

Handling and storage: Aseptic fruit concentrate can be stored at ambient temperature and has a shelf life of 24 months. For Juice concentrate, the shelf life is 6 months at ambient temperature and 12 months at chilled conditions. (<10 Deg C). The

Organoleptic features: The flavour, aroma, and taste of the fruit concentrate retain the nature of the original fruit as no preservatives are added.

Packaging & Loading: Aseptically in pre-sterilized aseptic bags placed with polyliner in food grade epoxy painted (inside) open-top MS drum. 80 Drums Per 20-foot Container and 108 drums loaded in a 40-foot container.

Difference between fruit concentrate/ fruit puree concentrate and Fruit juice concentrates

- Fruit concentrate is a general term that can refer to a product made by reducing the water content of fruit puree, or pulp.

- The process of making fruit puree concentrate involves removing a significant portion of the water from the original fruit juice or puree, resulting in a thicker and more concentrated product.

- Fruit juice concentrate specifically refers to a product that is made by extracting the water content from fruit juice, leaving behind a concentrated form of the juice. It is essentially the concentrated form of the liquid obtained directly from the fruit.

- In summary, while both fruit concentrate and fruit juice concentrate involve reducing the water content of fruit-based liquids, the term “fruit concentrate” is more general and can encompass concentrates made from puree, or pulp. On the other hand, “fruit juice concentrate” specifically refers to a concentrated form of the liquid extracted directly from the fruit.

Frozen puree/pulp cubes

- Frozen Puree Cubes are made from sound mature & selected ripened fruits.

- The process involves the selection of ripe fruits washing with disinfectant, final inspection, fruitmilling, pulping & finishing, preheating decantation and Pasteurization.

- The puree is blast-frozen into a silicon cube tray to get the cube shape and packed in a food-grade blue polyliner in a carton box & passed through a metal detector before being stored at -18 degrees C.

Handling and storage: Storage at below -18 ̊C in a Cold room. After Storing at -18 ̊C for more than 3 weeks, dice may assume the shape of a block, which can be loosened by Shaking the cartons gently, two to three times. Once opened, the remaining material should be returned to the cold room as early as possible to retain product quality.

Organoleptic features: The flavour, aroma, and taste of the frozen puree cubes retain the nature of the original fruit as these cubes are made from puree.

Packaging & Loading: The product is packed in blue colour food-grade PE bags & packed in 5-ply corrugated boxes. Up to 2300 cartons / 23 MT Net weight can be loaded per 40 feet FCL